In the world of manufacturing, precision and efficiency are paramount, and one tool that plays a vital role in achieving these goals is the سنبه پران mandrel. A cutting mandrel is a versatile device used in various industries to make precise cuts, shapes, and holes in a wide range of materials, from metal and plastic to wood and composites. Its significance lies in its ability to ensure accuracy and consistency in the manufacturing process, making it an indispensable tool for many applications.

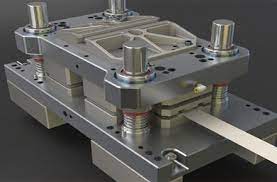

At its core, a cutting mandrel consists of a shaft or spindle, often made from durable materials like high-speed steel or tungsten carbide, which hosts a cutting tool or abrasive attachment. This cutting tool can vary in type, ranging from rotary blades and grinding wheels to specialized bits designed for specific tasks. The choice of cutting tool depends on the material being worked on and the desired outcome.

One of the primary advantages of using a cutting mandrel is its precision. The tool’s design allows for tight control over the cutting process, resulting in clean, accurate cuts that meet exact specifications. This level of precision is especially crucial in industries like aerospace, automotive, and electronics, where even the slightest deviation from the intended dimensions can lead to product defects or performance issues.

Additionally, cutting mandrels are highly versatile, as they can be adapted for various applications. In metalworking, they are used to cut, shape, and deburr metal components. In woodworking, they can create intricate designs and carve patterns with finesse. Moreover, they find application in the medical field, where they are employed to manufacture custom implants and prosthetics.

The use of cutting mandrels isn’t limited to shaping and cutting alone; they also play a crucial role in hole drilling. With specialized attachments, they can bore holes of different sizes and depths, ensuring precision in tasks such as plumbing, electrical installations, and machining operations.